Parcel sortation is a growing area of automation inside the warehouse. With the growth of ecommerce and faster delivery time requirements automating the operations is a key area of focus for companies.

With parcel sortation in mind our ecommerce sortation systems are designed to take away the manual handling and data inputting parts of the warehouse operations.

Automated areas:

- Auto ID – scanning barcodes, address labels, optical character recognition

- Weighing – weighing and storing data

- Volumetrics – automatically getting the size and volume of packages

- Singulation – auto sort packages to work in a system

- Sortation – sorting into lanes, cages, totes

- Label Application – automatically labelling packages with shipping labels

- Integration – integration with business systems

- Reporting and Analysis – data available reporting, how many packages, performance metrics

With a modular approach the Keymas ecommerce parcel sortation system can be designed to work with one or more of the modules with a design approach that can build a system to suit your business.

Contact us today to find out more about automating your parcel sortation at goods in or goods out and delivery.

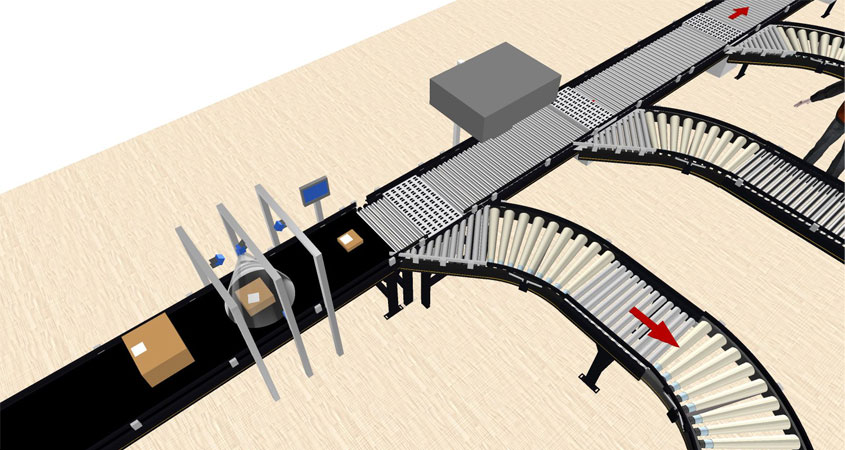

Conveyor system design

As part of the system design a conveyor system to move items into, through and out of the sortation system can be designed to fit the project profile. From small items to larger complex items having the correct conveyor is an important consideration. Our team have the experience to specify the correct conveyor. For more information on our conveyor systems view our page.

Auto ID

Barcode reading and vision systems mean that the items going through the system are logged and tracked.

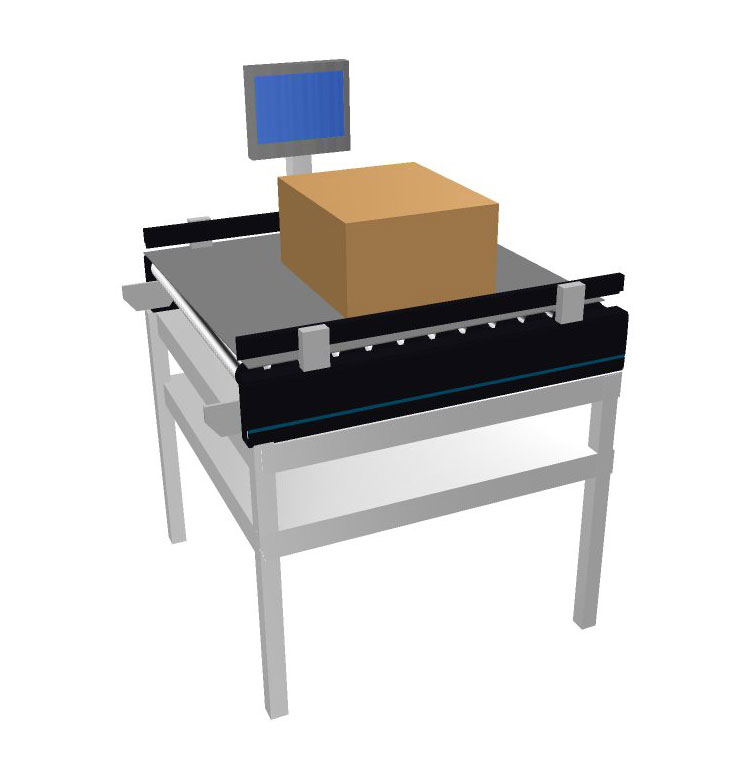

Weighing

Inline weighing takes the manual process out of weighing items. It allows a continuous weighing process to happen and weights recorded automatically.

Volumetrics

Items are scanned using a volumetric system to automatically capture the details of the size of the item. The measurements can be recorded and integrated into another system.

Auto label application

Automatic parcel label application takes away manual labelling operations. Shipping labels or tracking ID labels can be applied. Also, the shipping labels are scanned to be checked for good readability.

Sortation

Sorting the parcels into different destination lanes for quick loading onto delivery routes or country destinations. By automatically sorting the parcels into destination lanes saves time in manually sorting.

Integration

Pulling all the data together and then integrating into business systems creates a fast and interconnected solution. This takes away the need for manual data input.