When people imagine automation in logistics, they usually picture dark warehouses: vast, efficient spaces where robots, conveyors, and automated systems move goods seamlessly without a light switched on.

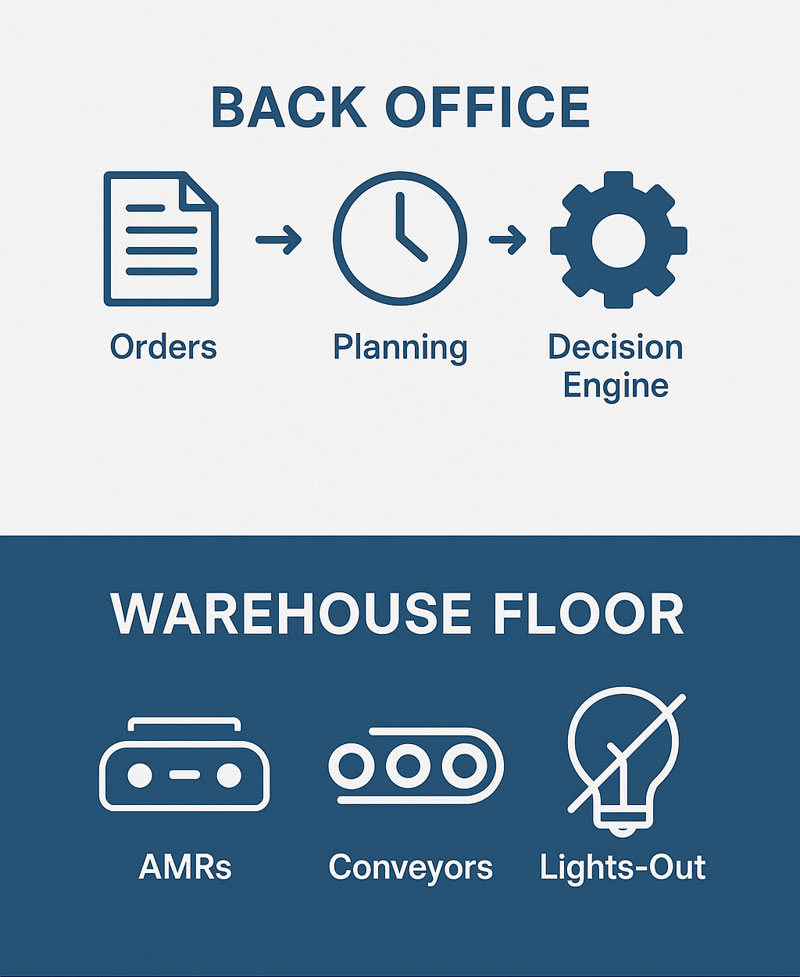

But behind every automated movement is a flow of digital decisions — orders processed, data synchronised, and stock planned.

That’s the back office, and it’s quietly becoming just as automated as the warehouse floor.

So, which will become “dark” first?

A dark warehouse is a fully automated facility that can operate with minimal or no human presence. Robots, AMRs, and automated conveyor systems handle the movement, storage, and retrieval of goods.

A dark back office, on the other hand, refers to business operations — order processing, purchasing, invoicing, and reporting — that are run by digital systems and AI rather than manual entry, emails, or spreadsheets.

Both aim for the same goal: speed, accuracy, and round-the-clock efficiency.

But they take very different routes to get there.

Automation Trends in the UK

While fully “lights-out” warehouses are still emerging, back-office automation is already mainstream.

AI adoption: According to government and industry data, around 75% of UK financial firms are already using AI in some form, with a further 10% planning to adopt within the next year.

RPA (Robotic Process Automation): Roughly 28% of UK firms are already using RPA, and 34% more are planning to roll it out, meaning over half of UK businesses are on the journey toward digital process automation.

Warehouse automation growth: The UK warehouse automation market is valued at around £1.7 billion, growing at 10–12% per year, but most deployments remain semi-automated — using AMRs and conveyors rather than full “dark” operation.

The numbers suggest that back-office automation will reach full autonomy sooner.

It’s cheaper, faster to deploy, and less physically constrained by layout, safety, or hardware limitations.

Why the Back Office May Go Dark First

Speed of implementation – AI and workflow automation can be implemented in weeks, not months or years.

Lower capital investment – No racking, robots, or hardware; just software and integration.

Data readiness – Companies already have huge volumes of structured data that AI can optimise.

Scalability – Once digital workflows are proven, they can be cloned across departments instantly.

In contrast, warehouse automation is limited by space, layout, and the physical world. You can’t deploy a robot in a corridor that’s too narrow or a building without the right infrastructure — but you can automate a purchasing process overnight.

The question is which one will become fully dark fisrt.

About Keymas

Keymas helps UK manufacturers and logistics businesses design and implement end-to-end automation, from digital workflows to physical warehouse systems.

Our mission is to connect the brains and muscle of automation — enabling smarter, safer, and more efficient warehouse operations.

If you would like to explore how to connect your back office to your warehouse automation strategy, get in touch.

We can provide expert advice and bring our knowledge and experience to your project.

Discuss your project