At Keymas, we’re working on an exciting project to take warehouse goods-in automation to the next level, from supplier portal to robot putaway.

The goal: to create a seamless, touch-free process where suppliers upload pallet ASNs (Advanced Shipping Notices) through a secure web portal, and robots handle everything from receipt to storage location — guided by intelligent software decisions.

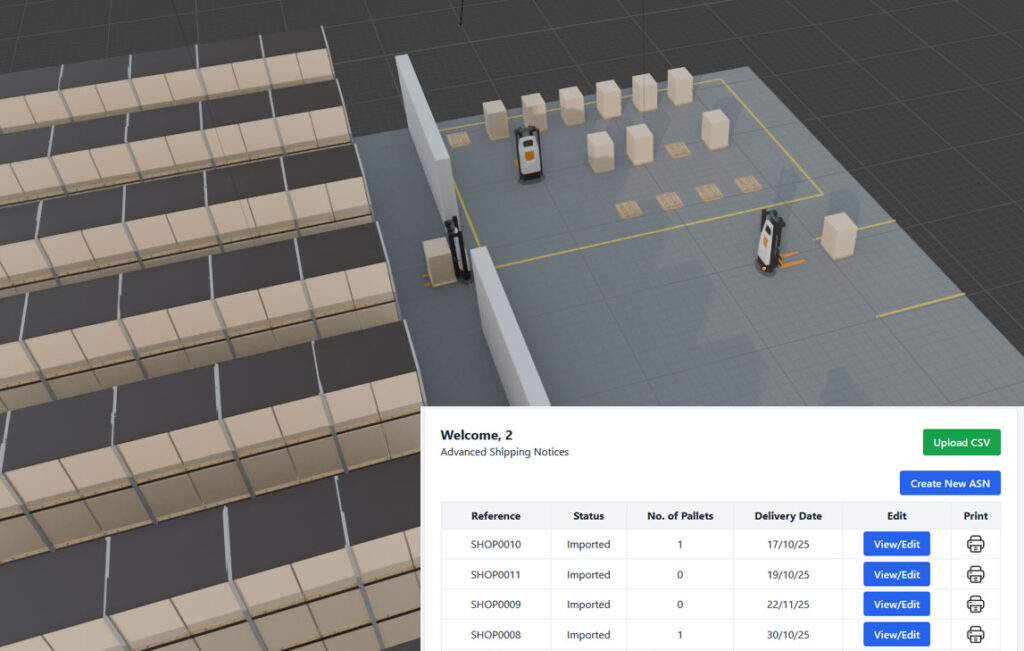

Suppliers log into a simple online portal to pre-register their deliveries. They upload pallet details, product SKUs, quantities, and batch data: giving the warehouse full visibility before the goods even arrive. This step allows accurate planning and slotting, and removes manual paperwork from the receiving process.

Once the delivery arrives, robots or scanners at goods-in identify each pallet via barcode or RFID, matching it automatically to the ASN. The system validates the contents, checks for discrepancies, and flags any exceptions instantly.

Our warehouse software, powered by Keymas KStore WMS, then determines the optimal storage location based on product type, demand frequency, and zone availability. No human decision-making is needed: the software evaluates live capacity data and directs the robots accordingly.

Finally, the AMRs (Autonomous Mobile Robots) take over. Guided by the WMS, each robot collects pallets from the receiving zone and transports them to the assigned racking location. Sensors and navigation mapping ensure smooth movement even in dynamic warehouse environments.

The result is a fully automated goods-in process from supplier input to pallet storage — reducing errors, removing bottlenecks, and unlocking real-time data visibility across the supply chain.

Why It Matters

For warehouses under pressure to improve throughput and reduce labour dependency, this kind of automation is a game-changer.

By combining smart software with physical automation, Keymas is helping customers achieve true “dark warehouse” capabilities — starting right at the goods-in door.

We can provide expert advice and bring our knowledge and experience to your project.

Discuss your project