Barcode reading systems are used in warehouses and production facilities across the globe to help manage inventory as effectively as possible. In organisations where 1000’s of goods are received and shipped on a daily basis, barcode readers offer a means of accurately identifying, tracking and recording items as they move from goods-in to dispatch.

If you’re considering investing in a barcode reading system, here are some top level benefits to help you understand more about how this technology could transform your business.

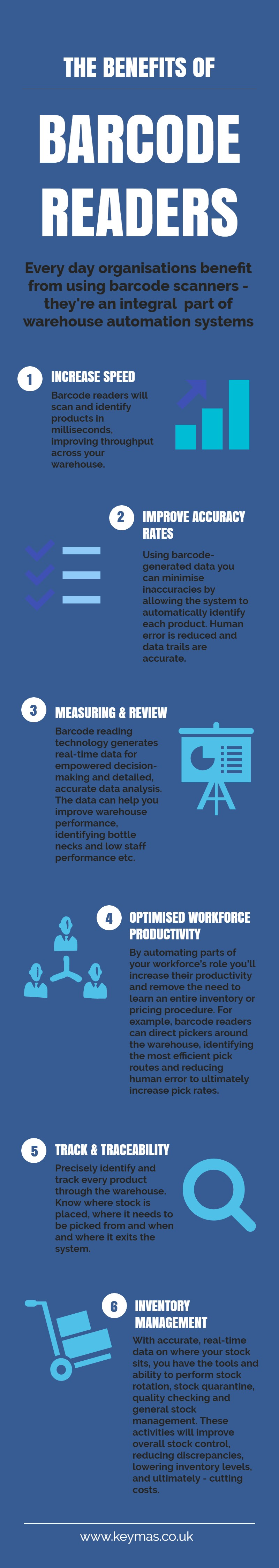

1. Increase accuracy rates

Barcode data entry minimises data inaccuracy by allowing the system to automatically identify each product. Human error is reduced and data trails are accurate.

2. Increase speed

Barcode readers scan and identify products in milliseconds, allowing you to improve throughput across the warehouse.

3. Measuring and review

With barcode reading technology you can use real-time data for empowered decision-making and detailed, accurate data analysis. The data will allow you to build a picture of your warehouse performance and identify bottle necks, low staff performance, efficiency etc

4. Improve workforce productivity

By automating parts of your workforce’s role you’ll increase their productivity and remove the need to learn an entire inventory or pricing procedure. For example, barcode readers can direct pickers around the warehouse, identifying the most efficient pick routes and reducing human error to ultimately increase pick rates.

5. Track and traceability

Barcode readers will allow you to precisely identify and track every product through the warehouse. You will know where stock is placed, where it needs to be picked from and when and where it exits the system.

6. Managing inventory

With accurate, real-time data on where your stock sits, you have the tools and ability to perform stock rotation, stock quarantine, quality checking and general stock management tasks. These activities will improve overall stock control, reducing discrepancies, lowering inventory levels, and ultimately cutting costs.

For more information contact us here.

Keymas are a conveyor systems and automation company. Contact us today to find out how we can help automate your business

Contact Us